When it comes to 3D printing materials there is no limit for it. There are a variety of materials available! which you can use to print your part from plastics nylon to wood all types of materials are available. From flexible and ductile materials to brittle and hard materials! all types are available which you can use to get your part done.

There is a lot of research going on in this field and new materials are being introduced every now and then.

Here in this article, we will look into some of the most widely used printing materials its application and benefits.

What’s in it for me?

Which Material Should We Choose?

Well answering this question is quiet a difficult task because it all depends on what we want to print and what quality we require for our part and what application purpose we are using the printed part considering all this we need to decide which material should we use.

If you want to print any part which you want it to be a food-safe! then you can choose materials like PETG. Using this type of material you can print any utensils. If you are an engineer and you want to test injection molding then instead of going with costly metals you can test your designs using thermoplastics such as nylon 3D printing material.

Other additive manufacturing technologies such as binder jetting and SLA as added an extra advantage for this printing industry.

This 3D printing industries has created an opportunity in manufacturing field like never before bringing many new materials into the market.

So its not a difficult task in choosing materials but before using any materials its good to know about the materials so lets look into some of the best materials available in the industry in this article.

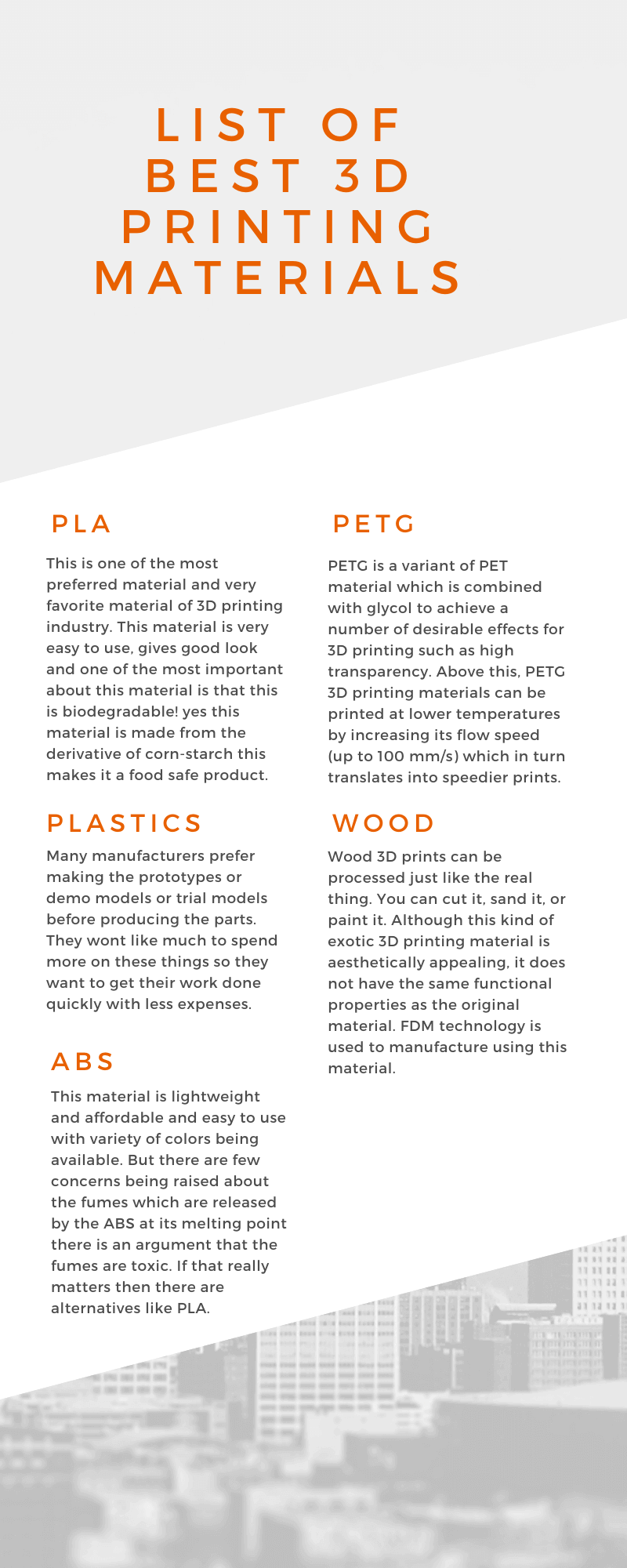

Plastics:

Today most of the products which we come across in our day to day life are made out of plastics so this technology is also not so different from that.

Many manufacturers prefer making prototypes or demo models or trial models before producing the parts. They won’t like much to spend more on these things so they want to get their work done quickly with fewer expenses. So they prefer plastic materials which are very cheap but provide the best quality, recently the professionals are focusing more on FFF rather than laser sintering.

PLA:

This is one of the most preferred material and very favorite materials of the 3D printing industry. This material is very easy to use, gives good look and one of the most important about this material is that this is biodegradable! yes, this material is made from the derivative of corn-starch this makes it a food-safe product.

This gives a very pleasant smell when it’s heated. Because of all these reasons, it is preferred more than ABS, it contracts less than that of ABS upon cooling, 3D printing technologies that support this material is FDM SLA SLS, and many more technologies also support this. PLA is available in a wide range of colors and it is shown in the picture below.

Nylon:

Nylon material turns out to be the premium choice from engineers to the artist. Because of its flexibility and strength, Nylon is also sometimes called white plastic. After printing the nylon parts it forms a rough surface at the top this can e removed by polishing.

Among FDM filaments, the layer bonding of nylon is stronger than all others, making it the ideal 3D printing material for parts that require good tensile and mechanical strength.

One of the disadvantages of this material is that it degrades due to humidity so if you want it to use for home 3D printing better store it in an airtight container.

FDM and SLS are the technologies that support this. This material is most commonly used for making models, medical applications, tooling, and visual arts.

ABS:

Do you remember the legos which you used to use when you were kids do you remember its quality? Yes, that was made using ABS materials from legos to the desktop monitors this material has a huge application.

This material is lightweight and affordable and easy to use with a variety of colors being available. But there are few concerns being raised about the fumes which are released by the ABS at its melting point there is an argument that the fumes are toxic. If that really matters then there are alternatives like PLA.

ABS also degrades when exposed to humidity so it is good to store it in vacuum bags. As ABS requires temperature around 250 degrees Celsius it requires a preheated bed before starting the printing process. This has a wide application in architecture models, DIY projects, etc. Some of the technologies where it can be used are in bidder jet, laser sintering, polyjetting, and FDM.

PEEK:

PEEK is the material which is preferred for high-performance materials production. This is resistant to high temperature, chemicals, and stress, parts prepared out of this material can be exposed to x-rays and gamma rays, to extrude this kind of material 3D printer has to reach up to 400 degree Celsius because of its properties it has a wide application in aerospace and automobile industries.

FDM and SLS technologies are used to print using this material as this has very good properties it is very difficult also to print so it is better to get your print done professionally if you really want to get your part done using this material. This material is biodegradable, hardwearing, and very strong makes it an expensive and most useful material.

PET:

The next material which we look onto is PET This is an alternative to ABS unlike ABS this does not release harmful fumes. This does not require any preheated bed. This material gives a glossy finish and is also food safe which makes it a very popular choice for many consumer products. Store PET 3D printing materials in vacuum bags or containers to protect against humidity. FDM technology is used to print this material. This material is food-safe flexible and is easy to use and it also gives a very smooth surface

PETG:

PETG is a variant of PET material that is combined with glycol to achieve a number of desirable effects for 3D printing such as high transparency. Above this, PETG 3D printing materials can be printed at lower temperatures by increasing its flow speed (up to 100 mm/s) which in turn translates into speedier prints.

PETG components are weather-resistant and are thus often used for garden appliances. Another selling point is its use as a food-safe 3D printing material. When using for home 3D printing, store this material in vacuum bags or containers to protect against humidity. This uses FDM printing technology and is used to produce concept models, DIY projects, etc.

Hips:

Hips have two most important applications mainly in providing support to the FDM and SLA printing HIPS works best when used in conjunction with ABS. This is also an extremely durable material that is suitable for shipping containers or other applications that require high impact resistance.

Note that HIPS emits vapors when printed, so air the room while using this material on a home printer. Like many other 3D printing materials, it is susceptible to environmental influences, so be sure to store it in airtight containers or bags.

Wood:

We know many general applications about the wood but did you ever know that you can create a 3D printed part using wood? Yes 3D printed parts can be created using wood filament as well. This is made by adding wood filaments to the plastic material.

Wood 3D prints can be processed just like the real thing. You can cut it, sand it, or paint it. Although this kind of exotic 3D printing material is aesthetically appealing, it does not have the same functional properties as the original material. FDM technology is used to manufacture using this material.

Conclusion:

So in this article, we came across various types of materials or filaments used in the 3D printing industry its applications, benefits and properties going through which you will now be able to choose which material you can use to create your model. In the next upcoming articles, we will look into some more information’s about this printing.

If you want to know in detail about various 3D printing software’s then you can check out our other blogs.

FAQs:

ABS is the best material available but it is not an eco-friendly option so if not ABS than we can go with PLA

When printed correctly Polycarbonates have tensile strength of about 9,008 psi and is a stronger option.

Photopolymer is used to make the 3D printers originally.

1Kg of PLA filament will be 110 meters long spool

Yes there are printer available to print food and those can print food as well.

PLA has 7,250 psi and is moderately strong.

No they are not so expensive but yes it depends on which spool you are using you get the PLA at around Rs.1000/kg

Yes there are metal 3D printers.

It depends upon the design and how big you want your product to be basically it takes 2 to 3 mins to print 1 gram of PLA

It varies from industry to industry some calculate it based on grams and some other may calculate it based on the time required to print the part so roughly they charge around Rs.15/gram

I am a mechanical engineer very passionate in latest technology and recent advancement in the field of technology and also a active Stock market investor.